PLASTIC DISC FILTERS

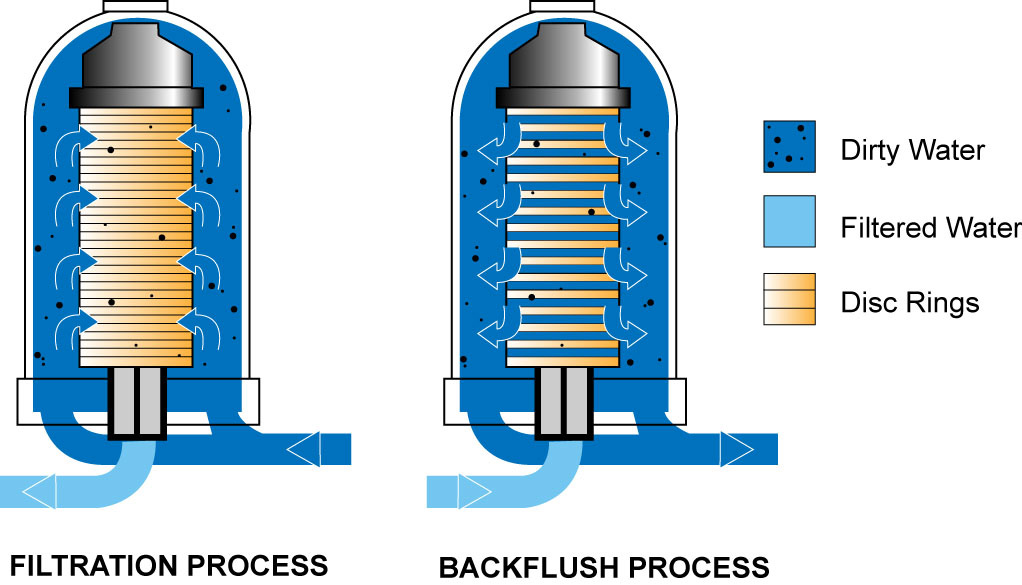

This technology uses plastic discs made of polypropylene that are stacked together under pressure and grooved to filter

particles of specific micron sizes. Each disc has etched grooves in a slightly different pattern array between the top

and bottom of the disc. When multiple discs are stacked and centered around a skeletal cylindrical structure, called

a spine, the discs form a hollow cylinder with the ends of the grooves exposed to both the inside and the outside

surfaces of the cylinder. The different groove patterns of the stacked discs create intersections of different sizes

to trap particles when cooling water passes from the outside to the inside of the hollow cylinder.

As particles are captured within the depth of the disc stack, a pressure differential is created.

Backwash is initiated when the preset pressure differential is achieved. The stack pressure is relieved and the filtered

water is forced through the disc stack in reverse through several nozzles within the disc stack spine. These nozzles

create a tremendous amount of turbulence that cleans the discs very effectively in 10 to 20 seconds.

Backwash is initiated when the preset pressure differential is achieved. The stack pressure is relieved and the filtered

water is forced through the disc stack in reverse through several nozzles within the disc stack spine. These nozzles

create a tremendous amount of turbulence that cleans the discs very effectively in 10 to 20 seconds.

Disc filters can remove both solids and organic particles effectively.

These filters also use much less water than other types of self-cleaning filters for backwash cycles, and tend to have

relatively lower installation and operating costs compared to other filters with equivalent filtration rates. Disc filters

can backflush multiple filters sequentially, and because the backflush cycle is sequential the filtration process is

seldom interrupted. Triggered by differential pressures or timing intervals, or a combination of both, the self-cleaning

process is fully automatic, requiring little maintenance.

Take a look at the line of self cleaning Super-T Disk Filters we carry.

|

Contact us TODAY to purchase industrial grade descaling chemicals or to discuss a water management solution for your specific application!

|

|