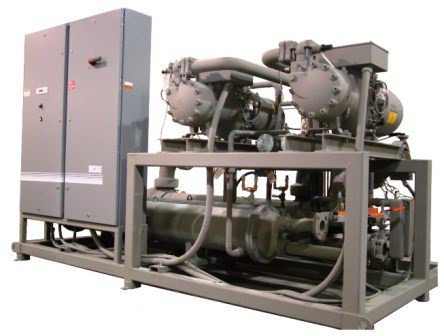

A Reciprocating Compressor is normally a heavy-duty, continuous service compressor. Cylinder construction

usually incorporates a water jacketed cylinder and water jacketed heads to remove some of the heat of

compression and also to improve the lubrication and reduce carbonization of valve parts. Water jacketing

around valve and packing is essential, since these are points of localized heating.

As time goes on, you will have limescale and rust accumulation inside the water jackets, which in

time, will overheat the air compressor and vacuum pump. This will also occur in your condensers, intercoolers and

aftercoolers.

As time goes on, you will have limescale and rust accumulation inside the water jackets, which in

time, will overheat the air compressor and vacuum pump. This will also occur in your condensers, intercoolers and

aftercoolers.

Cleaning Procedure

- Remove the limescale, waterscale and rust accumulation from the water jackets with

ScaleAwayBIO descaler without

disassembling the cylinders,

condensers, aftercoolers, or intercoolers.

- Remove the water in/out connection from each part and circulate

ScaleAwayBIO descaler for the recommended amount of time.

- After the circulation, flush with water and connect the water in/out connections back to the proper location.

A good proactive preventative maintenance program, with regards to waterside fouling, reduces unplanned shutdowns,

astronomical energy and operational costs, lower maintenance budgets and maintaining optimum operating efficiency

in water cooled air compressors and vacuum pumps.

Open PDF file to see a typical compressor descaling service Compressor Descaling Service

Contact us TODAY to purchase industrial grade descaling chemicals or to discuss a water management solution for your specific application!

|

|